Techology

Bioclar system — contemporary technology for wastewater treatment

The modular wastewater treatment plants CLARECO are wide applied in the modern world in reference to the kind of the waste water, which will be subject to treatment and the place of assembling the station. They are usually build as close as possible to the source of pollution and this saves additional costs for constructing sewage pipe-systems. The combined bioreactor can be cylindrical type, container type or cascade type, which makes the whole system compact and reduces the necessary building area. A guarantee for a long operating of the structure are the anticorrosion materials (PP). Parameters of the clean water requires to the Euro Union standards and BG-Standards, which allows reutilization of this water for industrial and agricultural necessities and etc. They are suitable for seasonal works and this is one of their greatest advantages in choosing water cleaning systems for resorts with a big alert of the number of the customers.

The modular wastewater treatment plants CLARECO are wide applied in the modern world in reference to the kind of the waste water, which will be subject to treatment and the place of assembling the station. They are usually build as close as possible to the source of pollution and this saves additional costs for constructing sewage pipe-systems. The combined bioreactor can be cylindrical type, container type or cascade type, which makes the whole system compact and reduces the necessary building area. A guarantee for a long operating of the structure are the anticorrosion materials (PP). Parameters of the clean water requires to the Euro Union standards and BG-Standards, which allows reutilization of this water for industrial and agricultural necessities and etc. They are suitable for seasonal works and this is one of their greatest advantages in choosing water cleaning systems for resorts with a big alert of the number of the customers.

Description of process technology for wastewater treatment

The Bioclar process technology complies with the most demanding ecological limits. The authors of this system succeeded in achieving the maximal possible level of optimising aerobic and anaerobic process in the wastewater treatment plant and concentrating them in a single vessel. The Bioclar technology combines several features, increasing its effciency and decreasing the cost.

Filtration based on the principle of the ascending sludge (sediment)

Sedimentation is a currently the most widelyspread separation technology, today. Its low specific rate of separation makes it slow and ineffective and mean time needs a great volume equipment. BIOCLAR system has higher specific rate of separation, using the principle of the ascending sludge (sediment) in a conical separator. Disperse system water-microorganisms flows into the separator through the bottom and while goes (flows) up, the floccules are falling down because of the gravitation forces. This way is made filtrating layer, which holds the smallest parts (fragments). Reaching one defined level, the sludge flows back to the denitrification zone.

High sludge concentration level

CLARECO wastewater treatment plants operate with high concentration levels of the active sludge, increasing the effectiveness and establishing good conditions for growing up the number of the microorganisms which are seeking for "food", organic mater in the input flow. By keeping biomass "super-active", microorganisms digested wide range of present organic matter.

All processes integarted in one single vessel

The traditional treatment process technologies use a separate vessel for nitrificatoin, denitrification and separation of activated sludge. BIOCLAR technology permits integration of all the process in one single vessel, decreasing demands on the build-up area and the cast.

Process specification

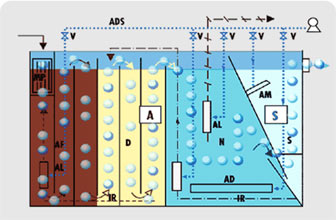

Biological reactor is the basic component of the CLARECO wastewater treatment plants. Within a single vessel, the reactor combines a mechanical treatment MP, activating section A, i.e. a modified activation process using a culture of an activated sludge mixture removing nitrogen and phosporus, separation section S, where activated sludge is separated from clarified water, an air-distribution system-ADS, electrical and control panel.

An activating zone A consists three sectors with specific conditions for biological treatment:anarerobic-fermentation zone AF, denitrification zone D and nitrification zone N. The zones are linked via defined openings and overflow and internal re-circulation piping IR. Mixing, circulation and re-circulation is provided by compressed air delivered by commpressor.

MP Mechanical treatment

AF Anaerobic-fermentation zone

A Activation zone

D Denitrification zone

N Nitrification zone

S Separation zone

AM Areation and Mixing Device

ADS Air-distribution system

IR Internal recirculation

V Valves

AD Aerators

AL AirLift

Wastewater treatment plant CLARECO B6

Wastewater treatment plant -10%

Wastewater treatment plant -10%

Wastewater treatment plant -10%

All Septic Tanks -10%

All Oil separators -10%